- About Us

- Major Business

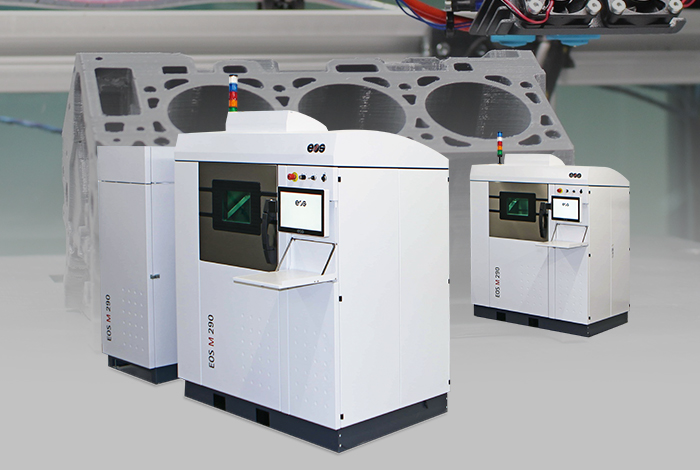

- Equipment

- Customer Service

- Reference

Business

Aviation Business

Aircraft Tooling/Parts

We manufacture aircraft equipment and sheet metal parts that are needed in various processes including, bonding, machinery, welding, and assembly, which are ordered by our major clients, including KAI, ASTK, KENCOA, etc.

Products

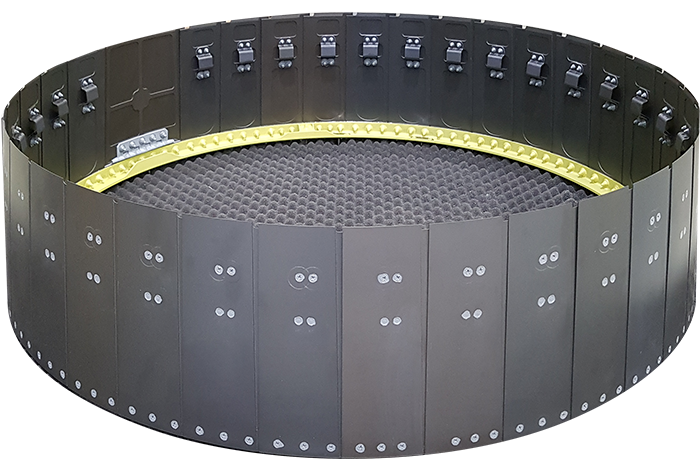

BNFM

DRJI, DRFX

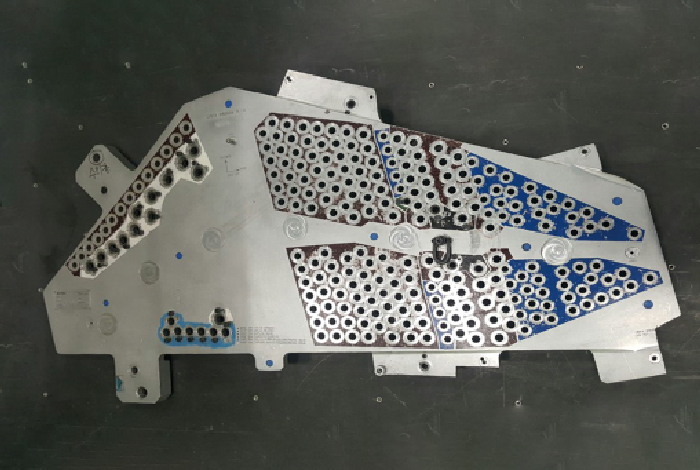

PLMO

DRJI, DRFX

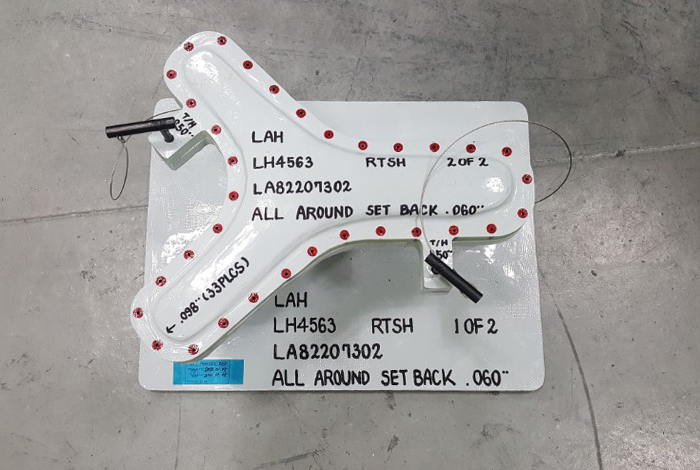

PDDY, PRAD

RTFX